How To Get Into Guitar Repair

We know, nosotros know… you'd rather play your guitar than spend time fixing it upward. Simply if you want it to play well, and if you want to be able to rely on it for gigs and jam sessions, then our practical guide to quick and easy tweaks and repairs – from truss rod tweaking to fret-slot fettling – will requite you lot all the info you need.

The common thread running through all our DIY and workshop features is our desire to encourage self-sufficiency in guitar owners, and relieve you money. If you understand the principles and become hands-on with basic maintenance, then you'll make informed decisions virtually when a trip to the luthier is really necessary, or whether a minor tweak at abode tin solve a problem. That's what this feature is all almost.

At that place are obvious parallels between automobile and guitar maintenance, and a guitar owner's human relationship with the luthier tin can often follow a similar dynamic to that of the car owner and their mechanic. For example, if you've always owned an old Alfa Romeo, you may be aware of something called the 'Italian tune-up'. The scenario goes something like this: the owner takes great intendance of his motorcar, never driving too fast, ever accelerating gently and keeping the revs well below the ruby line. But every few months, the car begins to feel sluggish and unresponsive, so the possessor decides it needs a tune-up and takes information technology to the garage.

The mechanic pretends to mind carefully equally the owner details all the symptoms, waits until he'due south out of sight, then takes the car for a long spin and then he can rev the crap out of the engine – literally. Having burned and blown away the carbon deposits that take formed because the engine isn't being used equally intended, the mechanic returns with a big grin and writes an invoice. The owner is delighted the 'tune up' has got the auto running equally it'due south supposed to once more, and the mechanic is delighted considering he knows he'll soon be doing it all again.

Withal if the owner was a bit more savvy, they could accept saved themselves some cash and hassle, and it's exactly the same with many common guitar ailments. By the terminate of this feature our aim is that you'll have all the knowledge you need to perform the guitar equivalent of the Italian tune-upward on your gear. So, with our sleeves duly rolled up, permit's crack on…

YOUR GUITAR MAINTENANCE TOOLKIT

Here's a suggested list of tools to invest in to carry out the bulk of routine guitar-maintenance tasks…

• Various apartment- and cross-head screwdrivers

• A set of Allen keys

• A cord winder

• Pliers with wire snips

• A soldering fe

• A multimeter

• Guitar lube

• Lighter fluid

• Fingerboard oil/conditioner

• A socket fix/truss rod tools

• Cease reviver/smoothen

• Spare batteries

1. TRUSS ROD BASICS

If any aspect of routine guitar maintenance comes closest to the Italian tune-up analogy, it's truss rod adjustment. Inquiry the subject field and you'll encounter dire warnings on the dangers of amateurs wielding truss rod wrenches and how this delicate performance must be left to 'qualified luthiers'. What constitutes a 'qualified luthier' remains a mystery; but on your side by side visit, effort asking to see your luthier's qualifications. I know exactly what the response would be if I asked my favourite luthier, but we wouldn't be able to impress it. Suffice to say, every 'qualified luthier' had to get-go somewhere – nigh probable past getting stuck in to the very tasks nosotros'll evidence you lot how to do in this feature.

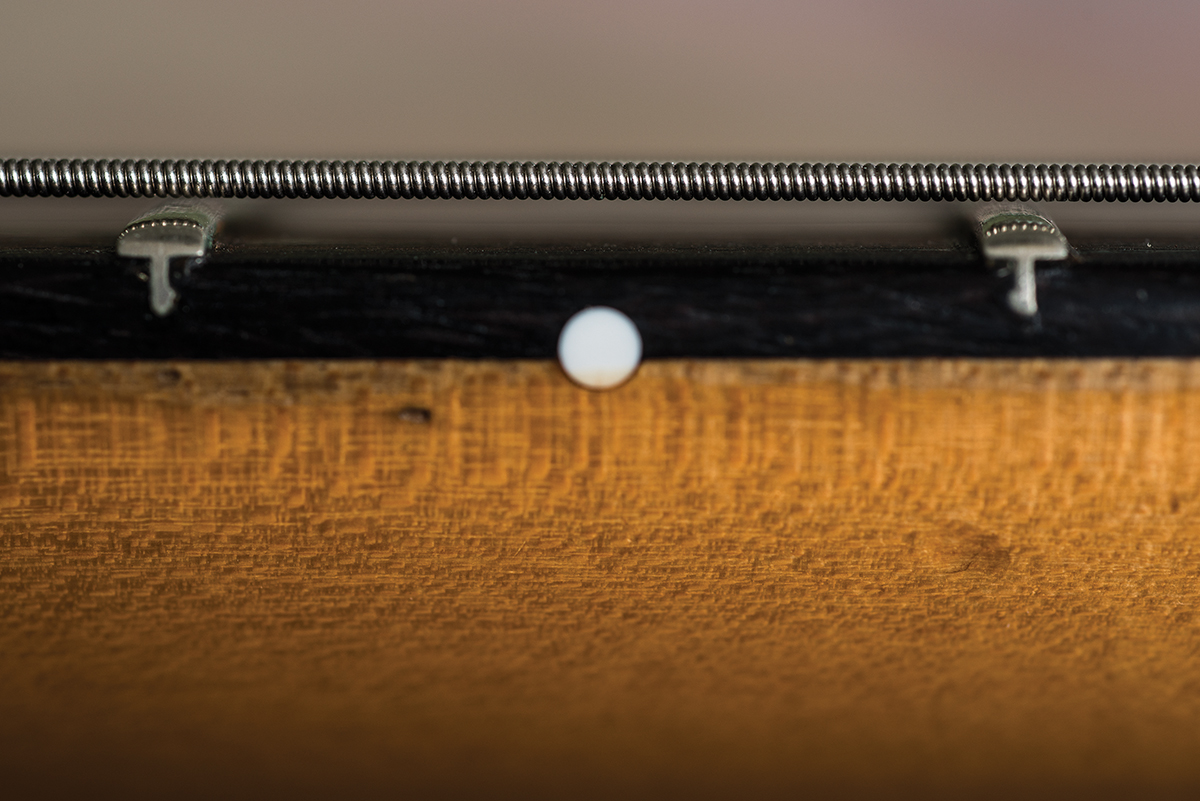

If the gap between the strings and the 7th and 8th frets is bigger or smaller than normal, your truss rod needs a tweak

Getting back to truss rods, many techs get busier twice a twelvemonth, when clients call to say their guitars need setting up. These periods tend to coincide with the weather getting colder during autumn and warmer during bound. In near instances, these changes in the weather will crusade necks to bow up or downwardly: the tell-tale symptoms are a change in a guitar's action, and intonation that sounds a bit off. If you think it through, it's highly unlikely that a span's height has spontaneously shifted, or its saddles accept moved – and on an acoustic, they can't move – so any sudden modify has to be attributed to a neck responding to changes in atmospheric conditions. Necks are e'er moving to some extent, which could be why your guitar feels better on some days than others. Truss rod adjustment may likewise be necessary if yous swap to a unlike string estimate, or fifty-fifty a new make of the aforementioned gauge.

The first step to accept is to determine what's going on with the neck. Merely iii specialist tools are required here – your ears, your fingers and your eyes. Some use feeler gauges, but in the existent earth of worn and uneven frets, their usefulness is moot. If the strings experience college than before and notes played at the 12th fret sound sharp of the 12th fret harmonic, the neck may take bowed upwards. Place one finger on the first fret of the 6th (depression E) string and the thumb of your other mitt on the same string at the fret where the neck joins the trunk, and and then check the gap betwixt the cord and the elevation of the seventh or 8th fret. There should exist a very slight gap, but if this seems greater than usual, that confirms at that place's a slight frontward bow and the truss rod needs to be tightened. The gap is chosen 'neck relief'.

The first step to accept is to determine what's going on with the neck. Merely iii specialist tools are required here – your ears, your fingers and your eyes. Some use feeler gauges, but in the existent earth of worn and uneven frets, their usefulness is moot. If the strings experience college than before and notes played at the 12th fret sound sharp of the 12th fret harmonic, the neck may take bowed upwards. Place one finger on the first fret of the 6th (depression E) string and the thumb of your other mitt on the same string at the fret where the neck joins the trunk, and and then check the gap betwixt the cord and the elevation of the seventh or 8th fret. There should exist a very slight gap, but if this seems greater than usual, that confirms at that place's a slight frontward bow and the truss rod needs to be tightened. The gap is chosen 'neck relief'.

Conversely, if your activity feels as well depression and you're experiencing fret buzzing and choke outs when bending strings, the neck may accept bowed backwards. If the intonation test reveals that fretted notes at the twelfth sound flat to the harmonic and the finger test shows the string touching the seventh or 8th frets, you tin can be pretty sure in that location's a dorsum bow, and it tin exist corrected by loosening the truss rod. Accessing the truss rod adjustment point isn't always piece of cake.

If it's at the headstock stop, in that location may be a cover that has to exist removed, or the end of the truss rod may be hidden away a centimetre of more inside a drilled hole. In a famous example of Leo Fender not actually getting everything right the kickoff time around, vintage Fender-style necks have their truss rod adjustment at the trunk end, meaning you may not exist able to conform the rod in situ without dissentious the pickguard or the cease.

Ideally, truss rod adjustments are fabricated while the neck is under string tension, but with those vintage Fender-style necks, this usually isn't possible. Fortunately, you don't have to remove the neck entirely to practice the job, merely yous will need to slacken the strings correct off. We propose putting a capo on the 1st fret to go along the strings in their nut slots and wrapped around their tuner posts before loosening the neck screws. Endeavour and ease the cervix upwards in its pocket until you run into the truss rod screw.

When adjusting truss rods, there are 2 key things to call back – always use the correct tool and piece of work slowly. If the truss rod access is at the body terminate, you lot'll most likely demand a sturdy cross-caput screwdriver. Gibson- and PRS-style necks usually feature a nut at the cease of the truss rod, so you lot can employ the accordingly sized socket from a socket prepare, or buy a wrench peculiarly for the task. Specialist suppliers such as Allparts UK and Tonetech may be able to help, and y'all can frequently observe what you need on eBay. Recessed truss rods at the headstock end normally require an Allen key. Sometimes, the hardest role is finding one of the right size, because Fenders fabricated in the Usa, United mexican states and the Far East all have different sizes – in metric and majestic. Again, you can use a specialist supplier, or accept your guitar to a really skilful hardware store that keeps a large selection of Allen keys sold individually.

Working slowly means checking the neck relief every quarter turn – and of grade, this takes a petty longer when you have to tighten the neck bolts and re-tune the strings every fourth dimension. To tighten a truss rod, turn information technology clockwise and to slacken it, turn anticlockwise. If the truss rod doesn't turn easily and you lot experience as if you're needing to apply real force, consult a pro. Truss rods are just designed for modest corrections and cannot set badly bent or warped necks. What'south more, only dual-activeness rods tin correct a dorsum bow. If, afterwards a full turn, the neck problem remains, it'south time to accept your guitar to the repairers. Fortunately, major issues seldom happen, and we can all perform minor truss rod tweaks that will keep our guitars playing every bit they should.

2. Issues WITH ELECTRONICS

We've all suffered from 'pot scratch fever' from time to time, and unwanted electrical noises periodically crop up with any electric guitar. The all-as well-familiar symptoms include crackly pots, viscid switches, intermittent jacks and hum. When these things happen, it's all too tempting to rip all the guts out and modify everything, but repairs are often an easier and cheaper alternative to replacement. Let'southward beginning with noisy pots, because they're the most common electronic problem. Before going any further, we need to determine if that scratchy sound really is coming from the volume pot or somewhere else. Try swapping to another guitar to encounter if that sounds scratchy, too. If every guitar sounds scratchy through your amp, the problem is more likely to be devious current from the amp leaking through the guitar cable.

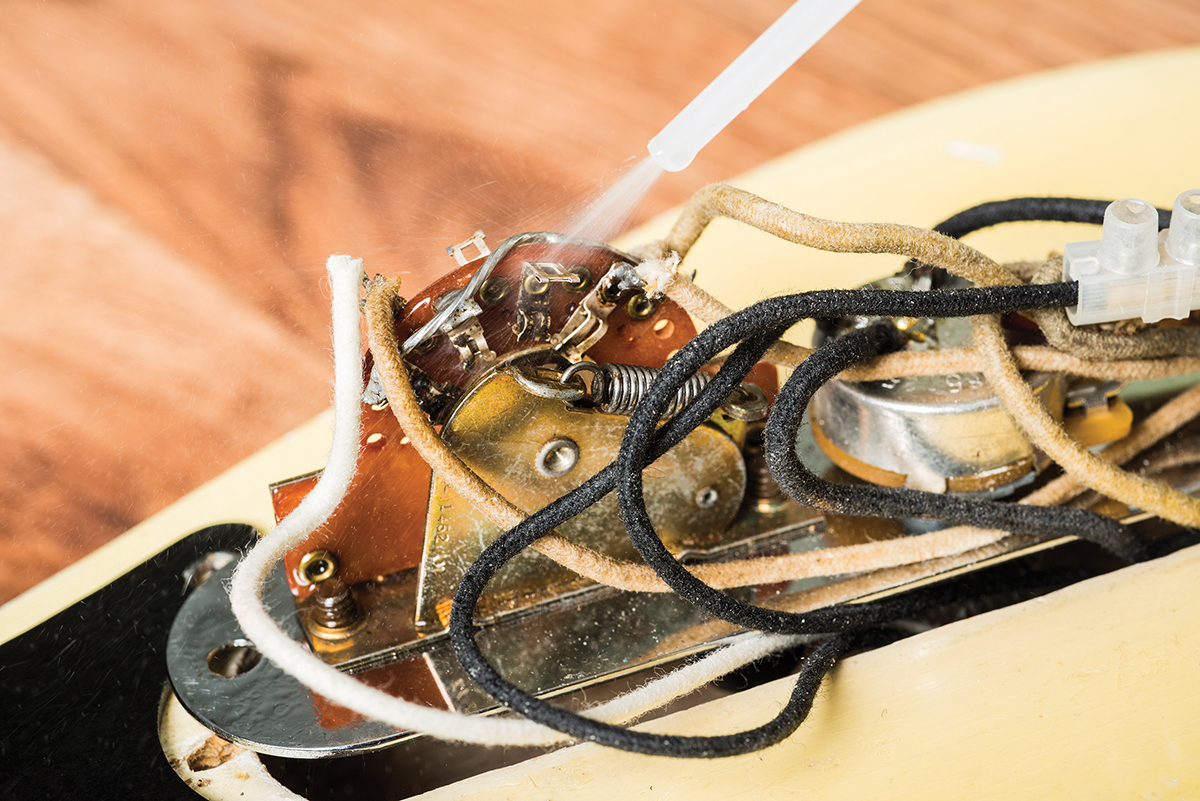

Many noise issues can be fixed with a the application of some contact cleaner, only if your wires are badly frayed or hanging off their contacts, then you'll need to get your soldering iron out…

Try putting a buffered pedal between your guitar and amp, and meet if that cures the racket problem. Whatsoever Boss pedal will practise, and many tuners are likewise buffered. If this cures the scratchiness, it'due south time to call the amp tech rather than your luthier. Incidentally, buffered pedals sometimes cure scratchy wah pedals, as well.

If you lot're still left with scratchy noises, there may be dirt or oxidisation in the potentiometers, so they'll demand cleaning. You'll need contact cleaner, which comes in aerosols with an extension tube for the spray nozzle. The tube lets you direct the product into the pot casing – so long as you tin can become at the pot. Things can be trickier with semis, because there's no direct access to the electronics. Cheque out a product called the Pot Cleaning Cap, because it slips over the pot shaft – one time you take removed the knob – and enables you to force cleaner into the pot. Popular cleaners include Servisol and DeoxIT. Some contain lubricant, likewise, which will help your treated pots turn more than freely. Just in example y'all weren't already aware, WD-40 is not a contact cleaner. After treatment, if the pot is still noisy or cutting out in certain areas, it probably does demand replacing.

3. SOCKET TO 'EM

Switches can get noisy and stiff. In fact, the 1963 Olympic White Strat we featured in the previous effect arrived with a switch that would barely move. After spraying the contacts with Servisol, we applied iii-In-ane oil to the switch's pivot point and permit information technology soak in. Afterward a few minutes, the 55-year-quondam switch was operating like it was brand new. Jack sockets sometimes go intermittent and if this is happening, hit a chord and wiggle the cable in the vicinity of the output socket. If signal cuts in and out, try a dissimilar cablevision, and if it stops happening, you lot'll know it'southward a cablevision consequence rather than the output socket.

Allow's assume swapping cables doesn't cure it, and the jack socket is the most likely culprit. Ii things are possible – firstly, the jack socket has lost some of its springiness and the tip connectedness is making intermittent contact with the jack plug. If you tin can go at the jack, endeavor gently bending the tip connector towards the centre using pliers.

The second event may be oxidisation on the contacts. You lot could try putting some contact cleaner onto a cotton bud and giving the contacts a scrub. Very fine Wet And Dry out abrasive tin can too be used to remove the gunk and reveal untarnished metal. If your guitar has started generating a load of hum, there could be a error with its ground connection. You can test this by connecting a wire from the metallic outside casing of the output jack (basis) to the guitar'southward bridge. If this reduces or eliminates the hum, you'll need to detect the cleaved connectedness. Alternatively, you can employ a multimeter to test for continuity between the bridge and basis. If in that location's no continuity, a visual inspection of the wiring will unremarkably identify a broken joint that needs to be resoldered.

four. TUNER TIPS

All moving parts tend to need occasional maintenance and tuners are a prime instance. Over time, they can get to feel loose and sloppy, or they may get the other way and become stiff, or fifty-fifty seize up. So, is it new tuner fourth dimension? Non necessarily.

Let's begin with the open-geared tuners that are commonly establish on acoustics, Gretsches and then forth. In that location are usually two screws on the gear plate that gear up each tuner onto the headstock. Remove the screws to remove a tuner, and then undo the screw holding gear onto the string post. When everything is dismantled, the metal parts can be cleaned with a naphtha (lighter fluid)-soaked cotton fiber bud.

If your open-gear tuners are as well stiff or too loose, you'll need to make clean out all the dirt and grease using naphtha, and so lubricate them with petroluem jelly. If yous take sealed-gear tuners, yous can tweak the tightness of the buttons themselves using the screws on the gear shafts

You lot may detect a load of caked dirt and dried grease. In one case clean, reassemble using petroleum jelly between all the moving parts and wipe off any excess before mounting the tuners dorsum on the guitar. The grease tends to solidify within the gear housings of Kluson-style tuners, too. Take the tuners off the guitar, heat them upward on a radiator or blast them with a hairdryer and affluent the gear housings with naphtha. Yous can forcefulness it in with a syringe, but with extremely stiff or seized tuners, you may need to soak them in the naphtha for some time.

If there are plastic buttons, endeavour and keep them out of the naphtha. Once the tuners are turning freely, flush out any remaining grease, permit the naphtha to evaporate, so utilize a syringe to inject petroleum jelly into the housing and wipe off any excess.

Even if your tuners are working fine, it'due south a sensible precaution to check the tightness of the fixing screws periodically. Tuners tin sometimes get a bit rattly, too, then cheque the tightness of the bushing nuts if your tuners have them. Sealed tuner buttons are always held onto the gear shafts by screws, and they can work loose. If in that location's whatsoever play in the buttons, tighten the screws – simply don't over tighten, considering the tuners will stiffen up and be hard to turn.

5. Common NUT ISSUES

Unless y'all're buying a reasonably high-stop guitar, most guitars are shipped with basics that have relatively shallow string slots. Cut nut slots to a perfect depth takes time, which isn't conducive to mass-producing guitars. Cutting them only deep enough and so the guitar plays, just high enough to prevent the open up strings buzzing against the 1st fret, ensures that in that location will be no rejects. The problem here is that high nut slots tend to make open chords audio out of melody.

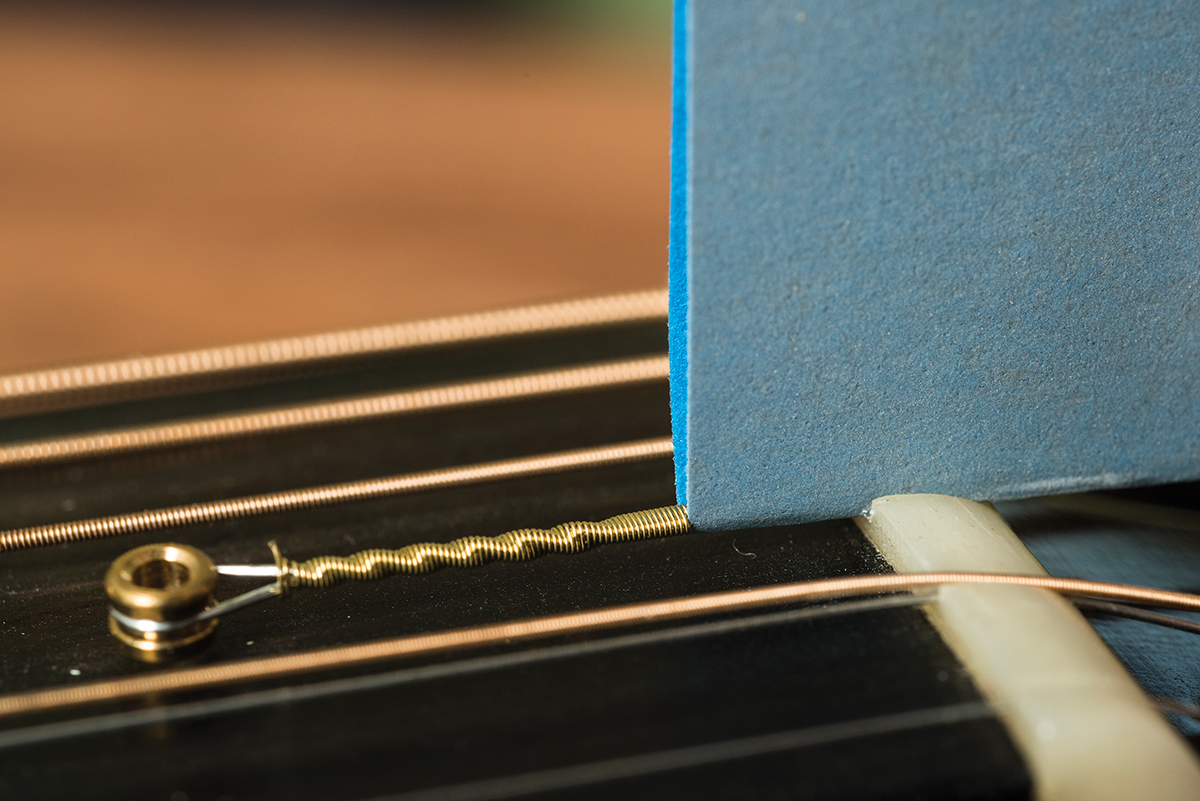

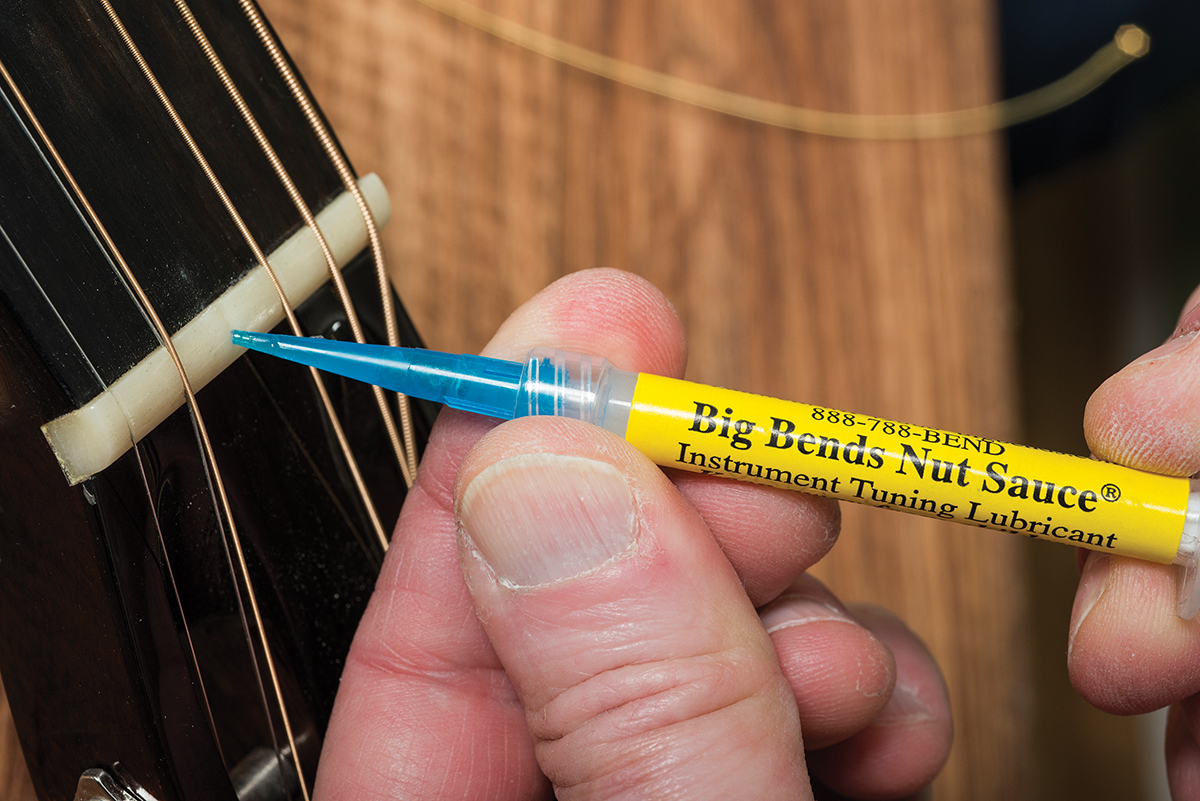

If your nut slots aren't cut properly, tuning bug can ofttimes follow – to become things moving smoothly once again y'all can use sandpaper to tidy upwards a slot, or alternatively lubricate it using chrome shine, Nut Sauce or other bespoke solutions

An Due east major chord may audio fine, but a D major doesn't. Tune the G string so the D major sounds sweet, and your E major will endure. High nut slots likewise make the guitar harder to play. Try putting a capo on the 1st fret, make certain all the open strings are in tune – a semitone upwards – and try those open chords once again. If your guitar plays easier and sounds more in tune, the nut slots probably demand attention and getting a luthier to do information technology is probably cheaper than buying a ready of nut files.

Italian tuning tune-up

Tuning instability is another issue associated with hastily cut nut slots. All likewise frequently, the tuners are blamed and replaced unnecessarily, but if you hear pops, clicks and pings when y'all're tuning up or bending strings, you can conclude that the strings are binding in their slots. Try wrapping some 1000-grit annoying paper around a string and using it to polish the slot. With materials such as bone, you can make the slots smoother all the same using chrome shine. Lubricating the slots with Tune-It, Nut Sauce, graphite powder or fifty-fifty petroleum jelly can likewise ensure your strings will glide easily.

What can exist washed about slots that are too low? In the long term, you may need to take the nut replaced, just at that place are workarounds that will get y'all through the adjacent few gigs – and may even become permanent.

Os nut slots can exist packed with baking soda, then a drop of water-sparse Super Glue is allowed to wick into the powder and set up solid – preferably overnight. You can use os dust, too, only the slot will have to exist recut with a needle file or the advisable cord wrapped with abrasive paper. If the slot was just marginally likewise low to begin with, add together simply a piddling powder rather than pack the slot to the skirt.

Plastic and nylon nuts may not exist such an piece of cake fix, merely if y'all're in a bustle, tiny pieces of paper can be pressed into the offending slots to enhance the strings. It may not look pretty, but information technology does the job. If a few of the slots are besides low, it may be easiest to shim the nut. Be warned that the nut and the finish can be damaged in the process of removing a nut, but find an online tutorial video and determine for yourself. A unmarried layer of 0.6mm veneer placed into the nut slot, before the nut goes back in, should be sufficient.

6. LOOSE VIBRATO Artillery

Whether it's a Strat-fashion 'synchronised tremolo', a Bigsby or a Floyd Rose, the thing about vibrato artillery is that you want them to be where y'all expect them to be. The big swoop-flop moment has come, you hit a perfect harmonic and observe yourself grasping at thin air because the arm has swung all the mode downwards. Mod vibrato assemblies frequently take grub screws that can be gear up to achieve the preferred balance betwixt solidity and swingability. One time you've found where the spiral is, yous can set-and-forget. However, vintage-mode Strat vibratos can be more problematic, considering they can go loose in the block. As well every bit refusing to stay put, in that location can be excessive play within the arm hole that makes the vibrato system loose and unresponsive.

Fixing a loose vibrato arm tin can be as simple as tightening a nut or dropping in some thread-seal tape

Some people abet dropping a spring into the cake that will compress against the arm every bit it's tightened and hold it business firm. We've institute that wrapping the arm's threaded section with PTFE tape from a plumbing-supply shop does the task only as well. The tape may need irresolute from fourth dimension to time, but information technology's dirt cheap. Bigsby arms are held in position by a spring pushing against a couple of basics. The amount of compression on the spring affects the arm's swingability, and you can adapt this past loosening the outer nut, repositioning the inner 1 and retightening the outer i. Once you lot accept the feel you want, apply a drop of Super Mucilage between the nuts and they'll concord tight.

vii. CABLE WOES

Information technology'due south probably happened to all of us at some point. Everything was fine before, merely when you flick the standby switch, there'south the sound of silence. Panic may seem advisable, but staying calm and trying to trace the trouble logically is more likely to go the show back on the route. Assuming the amp is okay and your guitar volume is turned up (aye, really), the most likely scenario is a communication breakup somewhere between your guitar and amp. Invariably, problems of this nature tin be traced to a dodgy cablevision.

When checking for your dodgy cablevision, be certain to unscrew and examine the solder joints to make sure the core and shield wires aren't touching

Try pulling your guitar cablevision from the pedalboard and plugging directly into the amp. If it works, do the same with the cable running from the pedalboard to your amp. If both are working, it's probably one of the patch cables on your board. Established audio-engineering practice is to piece of work backwards through the indicate path until you find the issue. In this example, that means pulling the patch cablevision from the output of the penultimate pedal in the chain and touching the tip with your fingertip. If you go dissonance through your amp, plug the patch cablevision back in and motion onto the next one. Repeat until you don't become any noise, and you've constitute the dodgy patch.

Y'all can also test cables electronically. If you own a multimeter, set it to continuity and bear upon the test probes to both tips of the jacks. If the connection is adept, the meter will buzz. Practice the same with the sleeve sections of the plugs. If that also tests 'proficient', merely the cable all the same doesn't work, attempt the test again with i probe on a tip and the other on a sleeve. If you go the continuity buzz this time, information technology means the cable has shorted out. Unscrew the jack plugs and examine the solder joints to bank check that the cadre and shield wires aren't touching. If the plugs await okay, the brusque is probably somewhere within the cablevision and you need a new one.

You lot can also perform rudimentary cable tests using a speaker chiffonier and a nine-volt battery pulled from a pedal. Plug the doubtable cable into the cab and bear upon the positive and negative battery terminals against the tip and sleeve of the cable'southward unused jack plug. If the cable is working properly, you should hear a momentary thump coming from the speakers.

8. STORAGE AND TRANSPORT

Hang them, case them, stand them or bag them… which selection is best for keeping your guitar safe? Some years ago, I interviewed Dave Edmunds, who explained one of the reasons he sold off his guitar drove to me: owning over 30 vintage guitars, he had to proceed them in cases. Every time he felt like playing one, information technology had to be pulled out of storage, cleaned and set with fresh strings, considering they ever went dead in the instance.

Keeping your vintage electric guitar in its case might non be the best thing for its hardware and terminate, while y'all'll want something more than robust than a vintage wooden hard example if you're planning to gig information technology

Past the time the guitar was in a playable condition, Edmunds had usually lost involvement and the guitar was put back into hibernation. Few players own 30 guitars, let alone vintage ones, but many of u.s. believe we're doing the right thing by keeping our guitars in cases. Unfortunately, this practice tin do more damage than good. As well the accelerated corrosion that invariably dulls the strings, frets and hardware, at that place's the event of aging celluloid plastic.

Over fourth dimension, the plastic emits vapours that eat into metal plating and can damage the finish. Vintage Gretsches are particularly notorious for 'binding rot', but in our experience, the celluloid binding survives only fine if the guitar is kept on a stand or hung on a wall. Some other advantage of hanging your guitars, or keeping them on stands, is that yous can just grab one whenever the mood takes you. A wall of guitars also looks pretty cool, and they'll never olfactory property musty or mouldy.

Some acoustic aficionados take a slightly dissimilar view, arguing that keeping all-solid guitars in sealed cases with controlled humidity prevents forest shrinkage and cracking. Maintaining constant humidity also ensures consequent tone and there are countless humidifiers on the market from manufacturers such as Martin, Planet Waves, D'Addario and Haven.

Left out in the rain

Keeping guitars in practiced status at home is 1 affair, but making sure they're rubber and secure when yous're out gigging and touring is something else entirely. Keeping your guitar safe is paramount and irrespective of how dandy some vintage guitars may be, the aforementioned cannot exist said for all vintage cases. The only matter an 'alligator instance' will protect a vintage Les Paul Junior from is the rain – and that's debatable. Even Joe Bonamassa isn't carting 'The Snakebite' around the earth in a 'Cali Girl' case. Although 70s and 80s Gibsons may be unloved, the Gibson 'Protector' cases of that era are regarded as the all-time ever, and that'south what Joe tends to use. If you travel to gigs by automobile and carry your own stuff, strong modernistic cases are your best bet. But if your gear is going into vehicles and planes alongside heavy objects similar amps, cabinets and drummers, a proper flightcase is indispensable.

9. BRIGHTER BUTTONS

Two issues tend to occur with strap buttons – straps falling off the buttons, and buttons falling off the guitar. The results tin be catastrophic as well as comedic, but there are diverse ways to ensure that your guitars hang tight.

If y'all prefer the look of vintage-style buttons but want to reduce the take a chance, many guitarists have successfully used the rubber washers from the stopper tops of Grolsch beer bottles. The strap goes on get-go, the rubber washer goes over the acme and the problem is solved. Information technology's an expensive style to exercise information technology and y'all end up with pink parts on your guitar, but at to the lowest degree you tin savour the beer. Alternatively, you can buy black safety-lock strap-lock washers on eBay, which toll less than £2 for a pack of ten.

Consider moulded plastic strap locks that slip over vintage-mode strap buttons – such every bit the Jim Dunlop Ergo. Perhaps the safest option is to go for total-on locking strap buttons, merely that will hateful taking off the former buttons to fit the new ones. Since they're merely held on with screws, if you can operate a screwdriver you lot can do the task yourself.

The trickier result is how to prevent strap buttons from pulling out if the screw is loose in the torso. Yous might consider drilling out the hole, filling it with wood glue and borer in a dowel. Once the glue is prepare, you lot can drill a new airplane pilot hole and so long as the diameter of the dowel is less than that of the strap button, the repair volition be invisible.

The 'matchstick trick' isn't but for sorting out your strap button – it's great for sorting out problematic pickguard holes as well…

Alternatively you tin can pack the loose screw hole with wooden matchsticks, toothpicks or cocktail sticks and a generous eject of wood glue. Again, you'll demand to drill a new airplane pilot hole for the button spiral, but the fix should be permanent. You might also try using longer screws than can bite into fresh wood, but ensure the bore is suitable for the button.

10. ROUTINE MAINTENANCE

Some guitar players struggle to differentiate between lovely vintage patina and obviously old clay and refuse always to clean their guitars. It's a personal matter, just we feel guitars that are regularly cleaned and maintained tend to operate more reliably.

Go into the habit of wiping down your strings with a clean material or some proprietary string cleaner after jamming or gigging. These products are cheap, quick and easy to apply – and past removing sweat, grease and clay from your strings, they may last longer and that will save you lot coin.

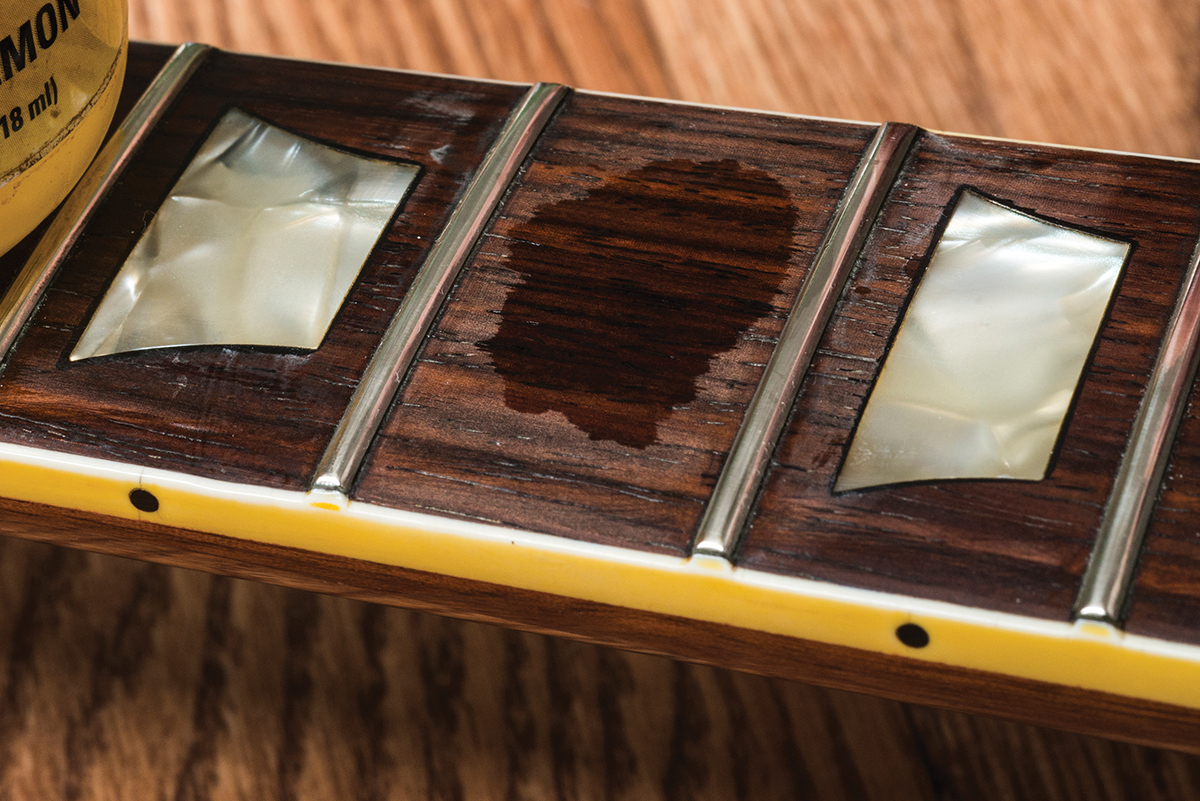

Two or three times a year, endeavour cleaning your fingerboard during a routine string change. Naphtha is ideal and y'all can use lemon oil or fretboard conditioner to ebony and rosewood 'boards to keep them looking and feeling proficient. Attempt polishing the frets, too, with some Micro-Mesh or Crimson Guitars' Fret Rubbers. Shine and shiny frets make cord bends experience easier.

Grease and crud can also become into the finish on the back of the neck, making information technology feel slow and mucilaginous. Again, naphtha can help to an extent, but the most effective production nosotros have tried is Virtuoso Premium Cleaner. It miraculously lifts out all the gunk while leaving the finish unscathed, and it's suitable for vintage guitars. A quick check of all the screws and fixings is also worthwhile to ensure strap buttons, tuners and pickguards are all properly fastened.

While you're at information technology, use guitar lube where needed – in nut slots, under string trees and on the pivot points of vibrato bridges. Lastly, run an electronics test to establish that everything is working properly. Prevention is ever better than a cure, and regular maintenance allows you to enjoy your guitars more than – and may salve y'all money.

When irresolute your strings, give the fingerboard a proper clean two or three times a yr – rosewood 'boards respond well to lemon oil

Source: https://guitar.com/guides/essential-guide/fix-your-guitar/

Posted by: vitalefords1948.blogspot.com

0 Response to "How To Get Into Guitar Repair"

Post a Comment